Leading the Way in Precision Leveling Since 1998

JIUYIZHONG Smart Equipment — Your Trusted Partner for Advanced Leveling Solutions in Metal Processing

Welcome to JIUYIZHONG Smart Equipment

Why Use Leveling Machine

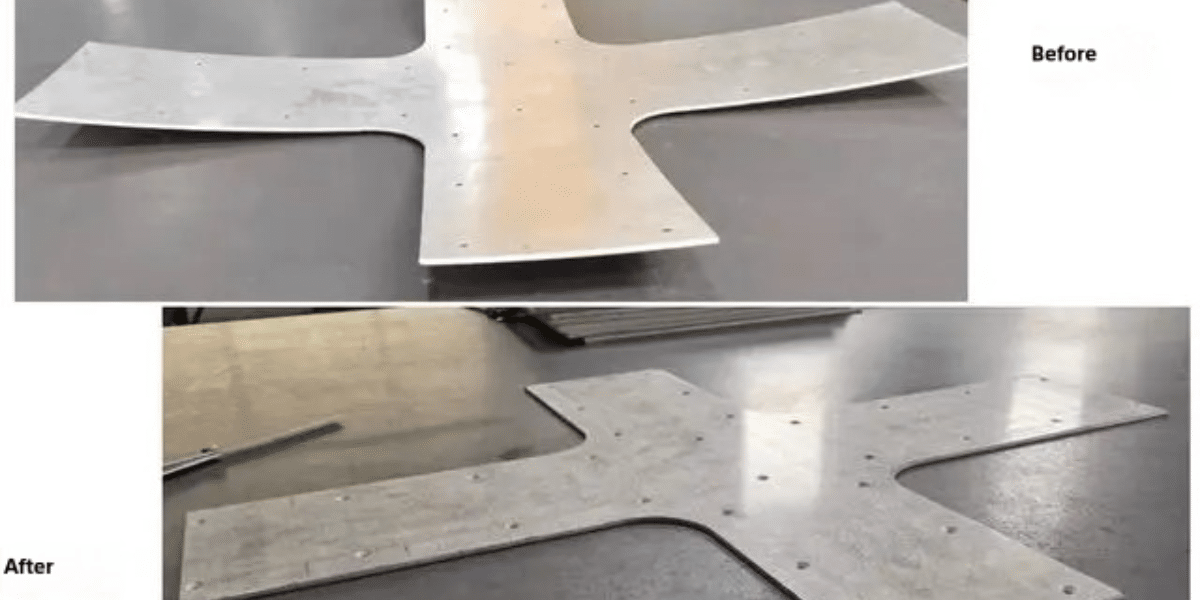

A leveling machine, also known as a straightening or flattening machine, works by passing metal sheets through a series of precisely aligned rollers.

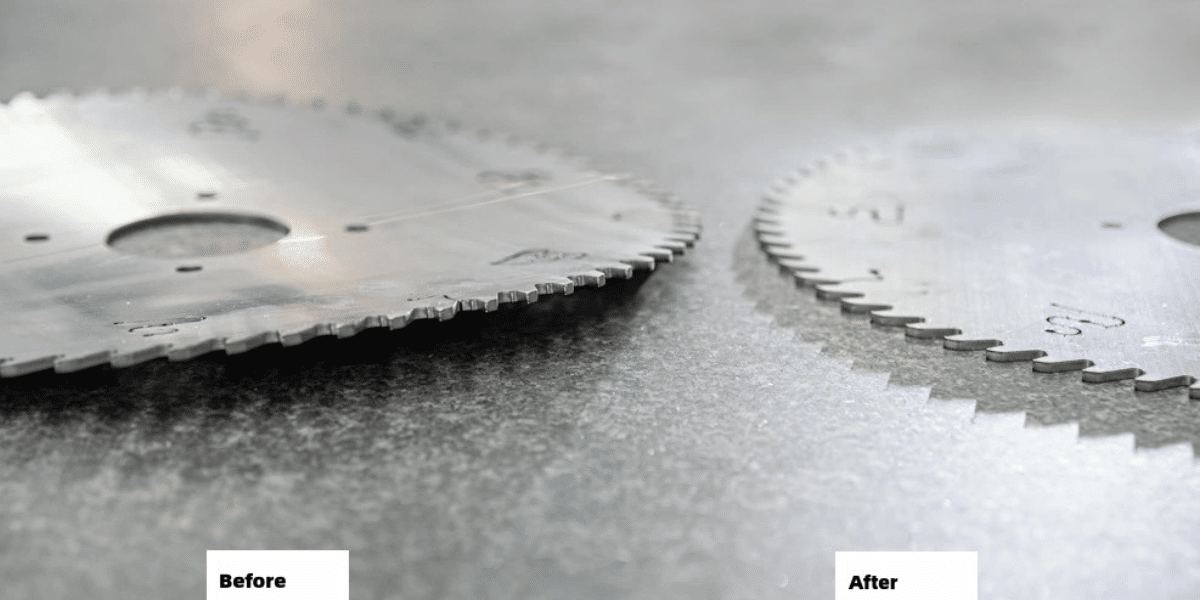

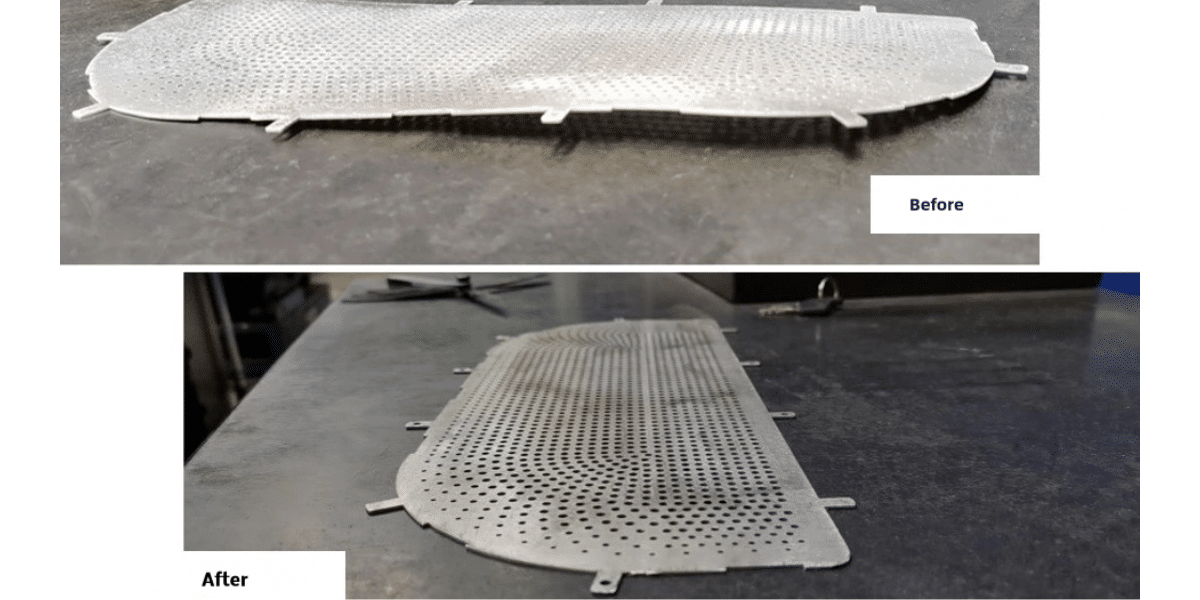

These rollers apply controlled pressure, gradually removing warps, bends, and internal stresses, resulting in a uniformly flat surface. The process ensures material flatness and dimensional accuracy, which is critical for quality fabrication and manufacturing.

The end result is a perfectly leveled sheet with minimal residual stress, ready for further processing or assembly in industries such as automotive, aerospace, construction, and electronics.

Video: The Metal Plate Leveling Process in Action

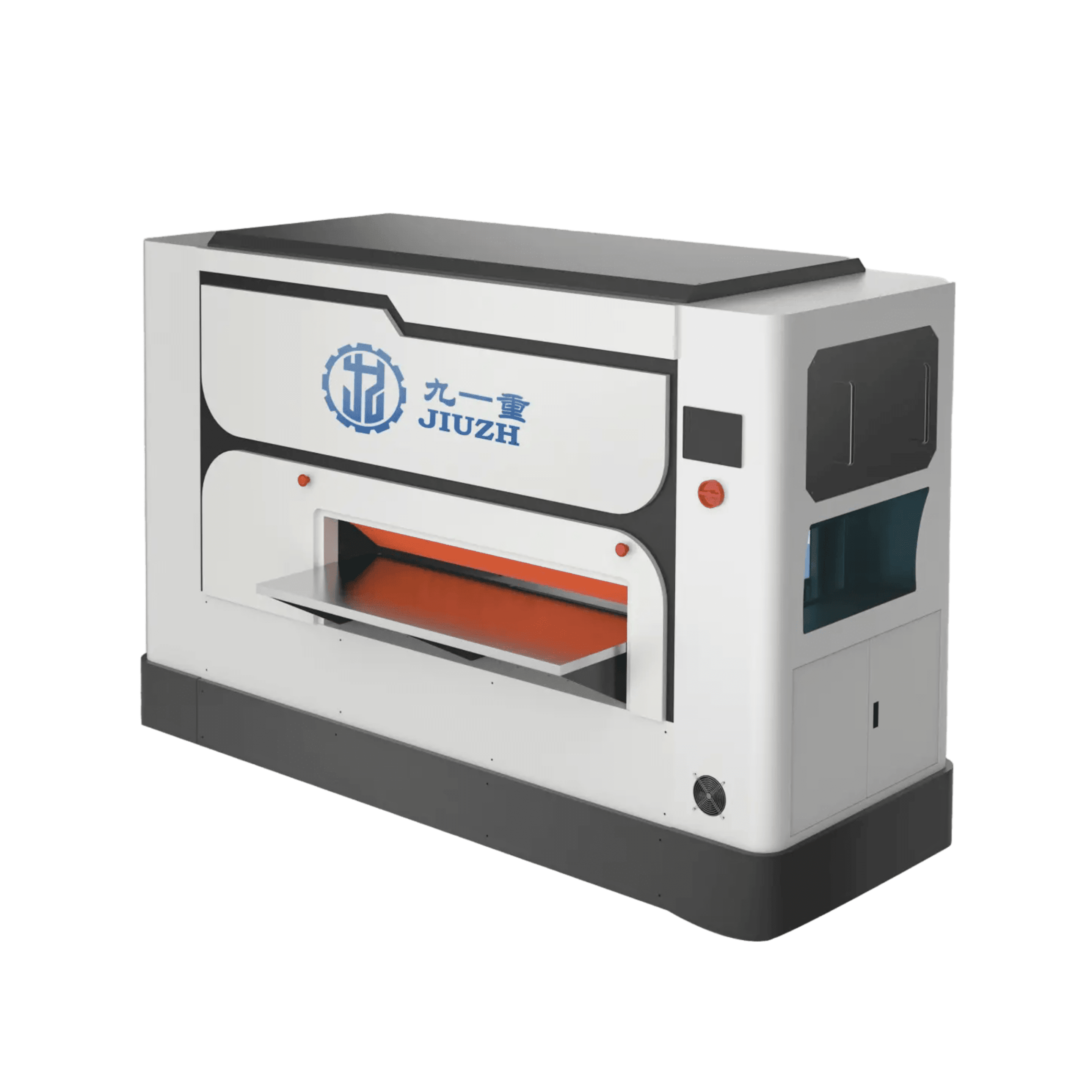

Explore Our Product Range

JZ-20 To 50

CNC Series

Material thickness:0.2-1.5mm to 0.8-4mm

Passage widths available:200-1300mm to 400-2200mm

JZ-60 To 120

CNC Series

Material thickness:1-6mm to 4-16mm

Passage widths available:400-2200mm to 400-3800mm

JZ-150 To 260

CNC Series

Material thickness:6-25mm to 15-60mm

Passage widths available:400-3800mm

Hydraulic precision leveler

Hydraulic Series

Customizable

JZ-YY-4000

Hydraulic Series

Material thickness:1.0-60mm

Passage widths available:4000mm

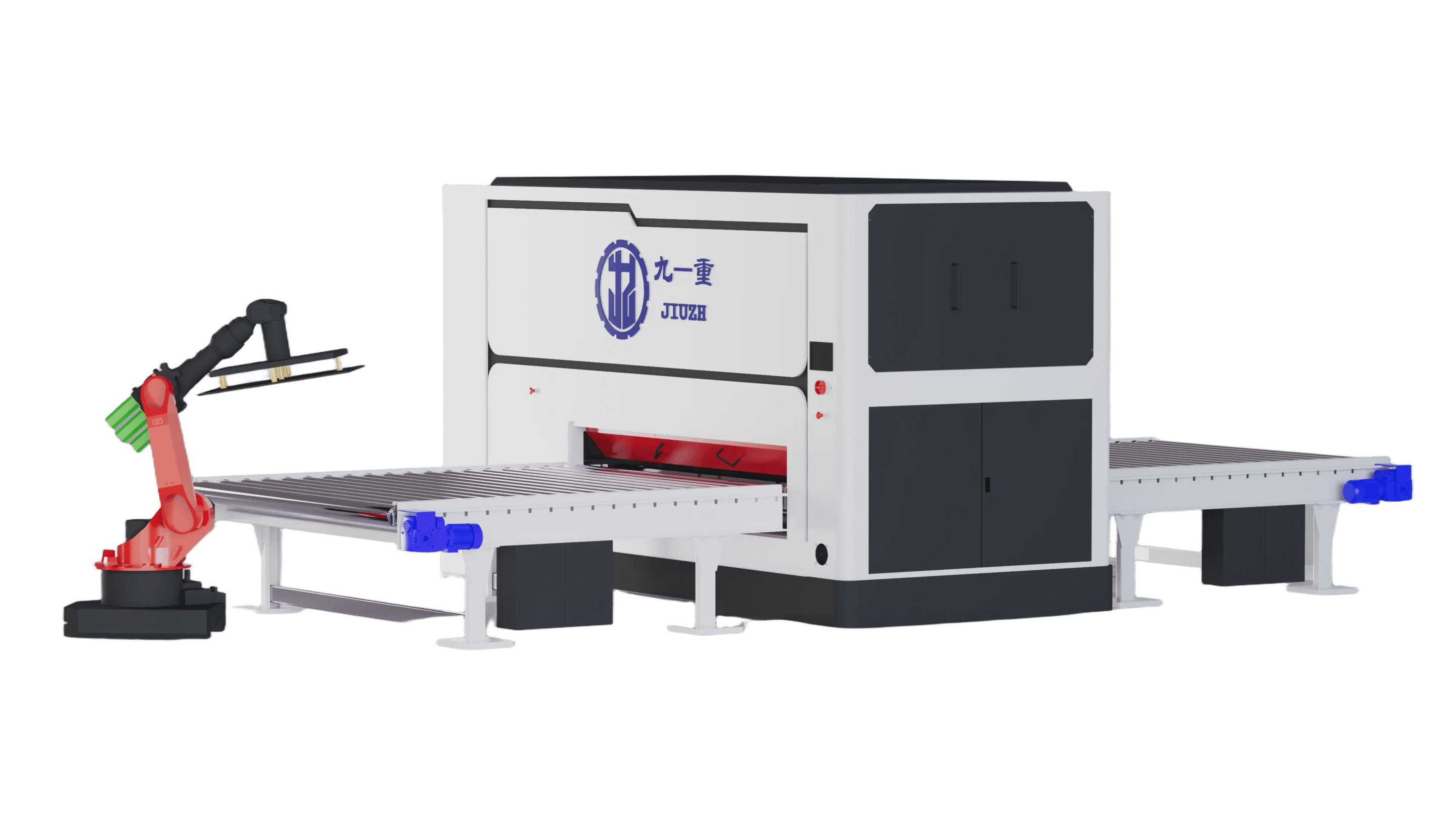

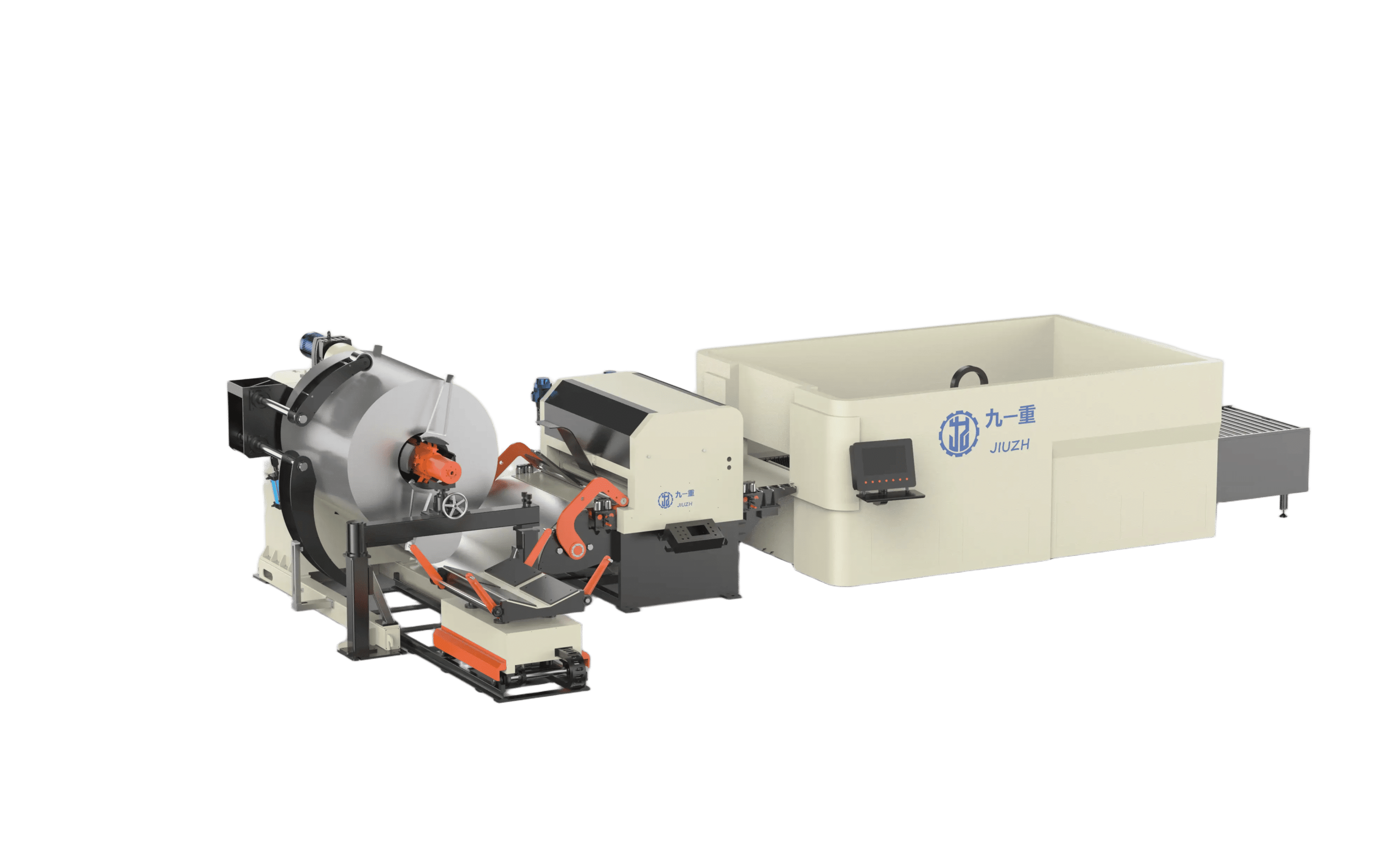

High Precision Blanking Production Line

Customizable

JN-12 To 20

Manual Series

Material thickness:0.1-1mm To 0.2-1.5mm

Passage widths available:200-700mm

JZ-32 To 60

Manual Series

Material thickness:0.5-6mm

Passage widths available:400-800mm

Flattening Effect Demonstration

Innovative Structures

Key Features of JIUYIZHONG Technology

Symmetrical Leveling Rollers

Our machines utilize multiple sets of symmetrically distributed leveling rollers to achieve high-precision straightening, reducing material waviness and stress.

Sturdy Frame Construction

Built with a robust frame and high-quality roller materials, our machines maintain stability and accuracy even under high-intensity conditions.

Advanced Lubrication System

The integrated lubrication system ensures smooth operation and longevity of the machine components, enhancing overall performance.

High-Grade Alloy Rollers

Crafted from Gcr15 alloy steel, our rollers undergo rigorous processing to achieve optimal hardness and durability, ensuring consistent results.

Precision Electrical Control

Our state-of-the-art electrical control system allows for precise adjustments and monitoring, providing users with full control over the leveling process.

Versatile Application

Ninefold leveling machines are versatile, suitable for various industries including steel, aerospace, and shipbuilding, enhancing the quality and accuracy of metal sheets.

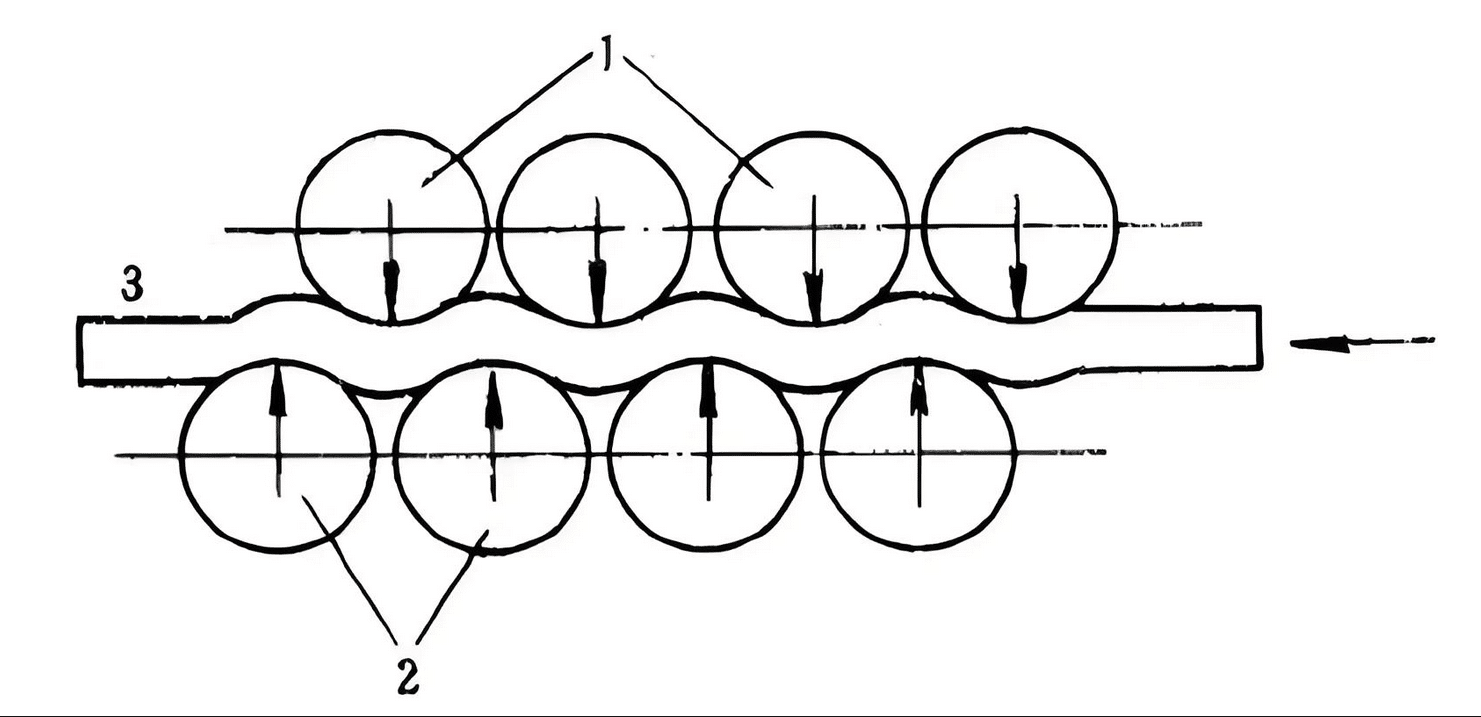

Understanding the Leveling Machine

Ninefold leveling machines operate on the principle of elastic-plastic deformation, utilizing the Bauschinger effect to achieve a uniformly flat surface on metal sheets.

Elastic-Plastic Deformation

During the leveling process, metal sheets are repeatedly stretched and compressed between upper and lower rollers, undergoing multiple alternating bends to reduce waviness.

Bauschinger Effect

The Bauschinger effect helps in transforming multiple curvatures into a single curvature, resulting in a flat and stress-free metal surface.

Precision and Reliability

Our machines ensure minimal residual stress and high precision, making them ideal for industries requiring exacting standards in metal processing.

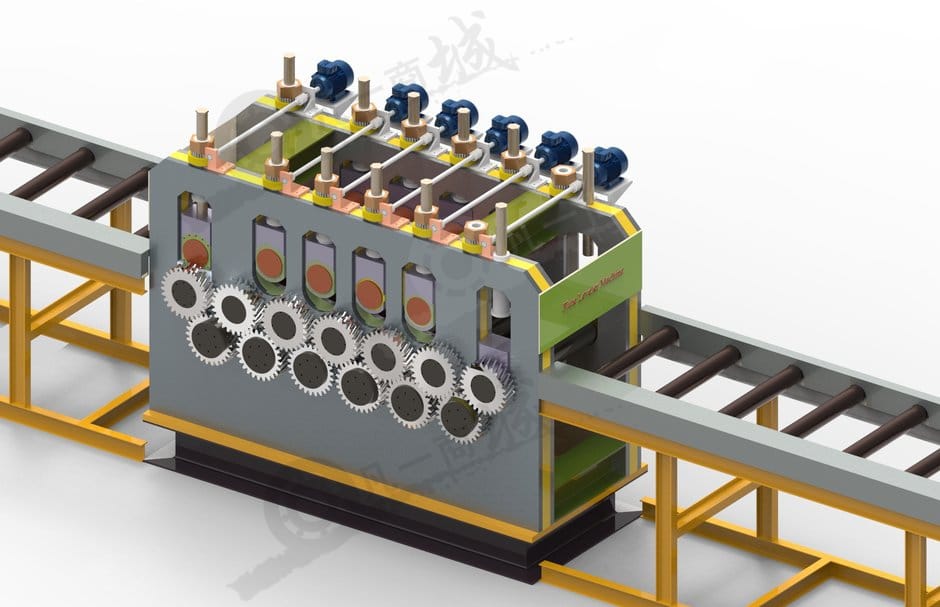

Main Components of the Leveling Machine

The leveling machine is composed of several key components that work together to ensure precise and reliable performance. The frame provides structural support, while the roller part, which includes both working and supporting rollers, performs the actual leveling. The movable crossbeam can be adjusted to accommodate different material thicknesses. The pressure-down corner mechanism ensures consistent pressure application. The main transmission system, driven by a motor, powers the rollers. Additionally, the lubrication system maintains smooth operation, and the electrical control system allows for precise adjustments and monitoring.

Roller Part

The roller part is the heart of the leveling machine. It consists of working rollers that directly interact with the material and supporting rollers that provide additional stability. These rollers work in tandem to bend and straighten the material, reducing waviness and internal stress.

Movable Crossbeam

The movable crossbeam can be raised, lowered, and tilted to meet the leveling requirements of materials with varying thicknesses. This flexibility ensures that the machine can handle a wide range of materials effectively.

Main Transmission System

The main transmission system is responsible for driving the rollers. It uses a motor to ensure consistent and powerful rotation, which is crucial for achieving precise leveling results.

Our Product Range

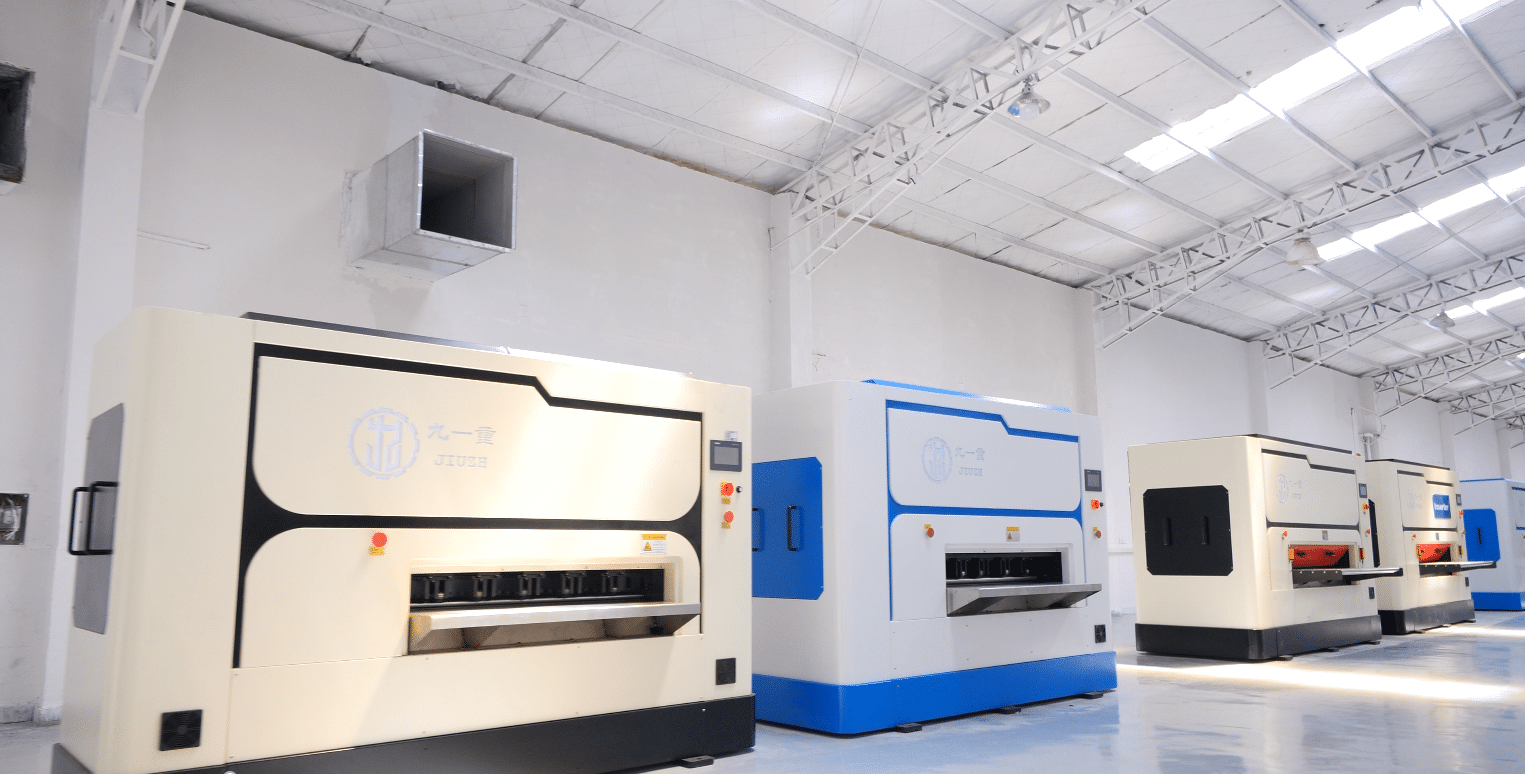

Discover the diverse range of high-quality leveling machines offered by JIUYIZHONG Smart Equipment, designed to meet various industrial needs.

CNC Series

Our CNC series offers precision and efficiency, ideal for complex leveling tasks requiring high accuracy.

Hydraulic Series

The Hydraulic series is known for its robust performance and reliability, perfect for heavy-duty applications.

High Precision Series

Engineered for utmost precision, this series ensures minimal residual stress and superior flatness in metal sheets.

Manual Series

Our Manual series provides cost-effective solutions with reliable performance for smaller scale operations.

Application Scenarios for Leveling Machines

Aerospace Flattening

- Aircraft Skins, Wing Panels: Adapt to extreme environments and ensure material strength and durability.

- Spacecraft Structural Components: Process high-strength aviation materials, such as aluminum alloys and titanium alloys.

Shipbuilding Industry Flattening

- Hulls, Decks, Interior Structures: Flatten metal plates in shipbuilding.

- Corrosion Resistance and Weather Resistance: Process shipbuilding steels and special alloys to ensure durability.

Metal Furniture Manufacturing Flattening

- Table Tops, Chairs, Bed Frames: Ensure the structural stability and design precision of metal furniture.

- Durability and Design: Provide consistent flatness to create high-quality metal furniture.

Our Valued Partners

What Our Clients Are Saying

“The precision and efficiency of JIUYIZHONG’s machines have transformed our production process. We couldn’t be happier with the results!”

Johnathan M.

Production Manager, Automotive Innovations Inc.

“JIUYIZHONG’s custom solutions have been instrumental in meeting our unique manufacturing needs. Their expertise is unmatched!”

Emily T.

Chief Engineer, Tech Solutions Ltd.

“We’ve seen a significant reduction in material waste since implementing LevelingMaster’s machines. Their commitment to sustainability is commendable.”

Jay R.

Sustainability Officer, Green Manufacturing Co.

“The integration of automation in JIUYIZHONG’s equipment has streamlined our operations, saving us both time and resources. Truly cutting-edge technology!”

David L.

Operations Director, Efficient Engineering Group