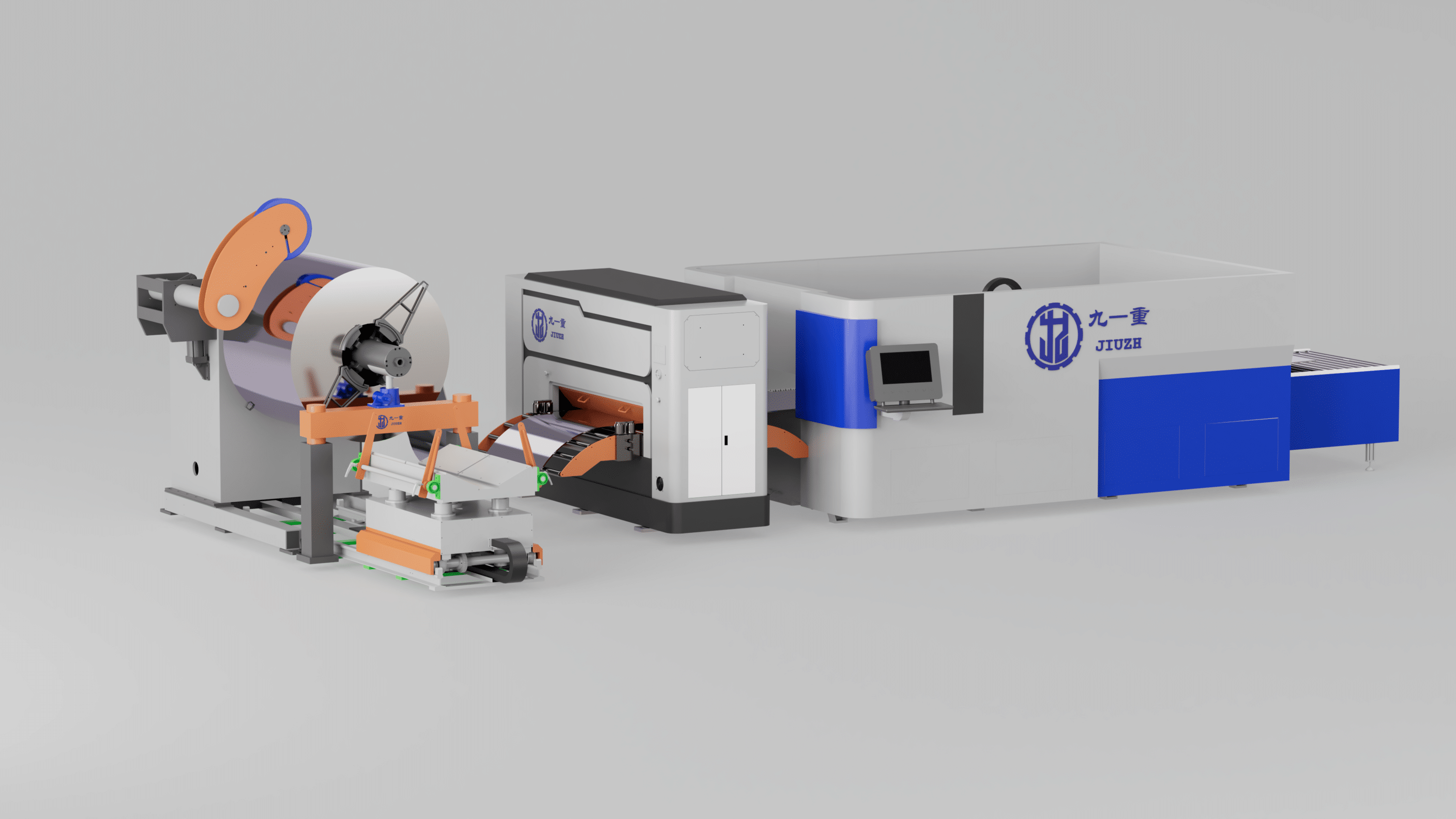

Precision and Efficiency in Metal Cutting

Key Features of Our Laser Blanking Lines

High Precision Cutting

Achieve exceptional cutting accuracy with our high-power laser beams, suitable for precision manufacturing.

Advanced CNC Control

Our CNC systems ensure precise control over cutting paths and patterns, enhancing flexibility and efficiency.

Automated Feeding System

Streamline your production with our automated feeding systems, designed to optimize material handling and reduce manual intervention.

Understanding Laser Blanking Technology

Laser cutting involves focusing a high-power laser beam on the material surface, causing it to melt or vaporize and form a precise cut. This process is controlled by a CNC system, which directs the laser along the programmed path.

The CNC system plays a crucial role in laser blanking production lines, ensuring that the laser follows the exact cutting pattern required for each job. This automation enhances accuracy and consistency, making it ideal for high-precision manufacturing.

Our laser blanking lines are equipped with advanced components such as laser generators, cutting heads, and protection systems, all working together to deliver superior performance and safety. These systems are designed to handle a variety of metal sheets, including stainless steel, carbon steel, and aluminum alloys.

Get Your Custom Quote Today!

Ready to elevate your production efficiency and precision? Contact us now to learn more about our state-of-the-art laser blanking production lines. Our experts are here to provide you with detailed information and a customized quote tailored to your specific needs.