JZ-150 To 260

Our Expertise in Leveling Technology

Leveling machines play a crucial role in various industries by ensuring the flatness and smoothness of metal plates. These machines are essential in sectors such as steel production, aerospace, shipbuilding, and non-ferrous metals. By eliminating internal stresses and correcting surface irregularities, leveling machines significantly improve the quality and precision of metal processing, paving the way for superior end products.

Product Specifications Parameters

| information | ||||

| Model-Z |

JZ-150 4-HIGH LEVELING/ 6-HIGH LEVELING |

JZ-180 4-HIGH LEVELING/ 6-HIGH LEVELING |

JZ-220 4-HIGH LEVELING/ 6-HIGH LEVELING |

JZ-260 4-HIGH LEVELING/ 6-HIGH LEVELING |

| Max.criteriom width | 400-3800mm | 400-3800mm | 400-3800mm | 400-3800mm |

| Roller diameter | 150mm | 180mm | 220mm | 260mm |

| Max.thickness | 25mm | 35mm | 45mm | 60mm |

| Thickness range | 6-25mm | 8-35mm | 10-45mm | 15-60mm |

| Leveling roller quantity |

15pcs (Upper 7pcs/ Lower 8pcs) |

15pcs (Upper 7pcs/ Lower 8pcs) |

13pcs (Upper 6pcs/ Lower 7pcs) |

13pcs (Upper 6pcs/ Lower 7pcs) |

| Min.work-piece size | 60x280mm | 60x350mm | 60x420mm | 60x520mm |

| Leveling roller gap adjust method |

Four points auto.Adjust driven by servo motors | |||

| Leveling speed | 0-12m/min | |||

| Voltage | AC3phase 380V 50HZ(Or local voltage) | |||

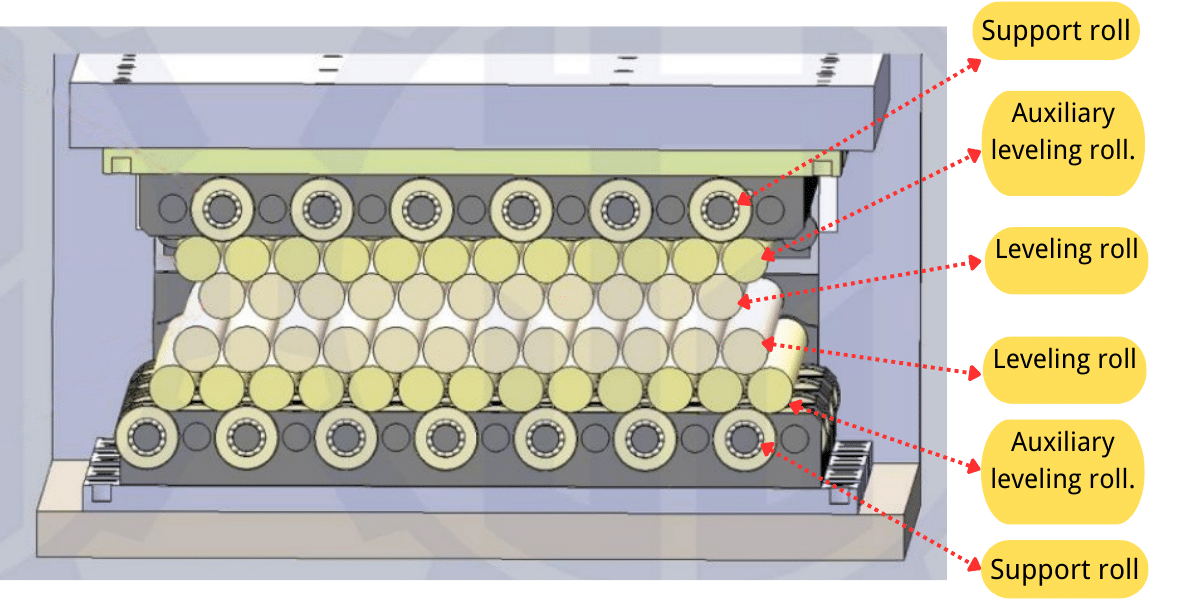

4-HIGH LEVELING PRINCIPLE

- Principle: Utilizes the “elastic deformation” of the material, allowing the sheet to undergo controlled bending between upper and lower rolls, moving in alternating directions to generate multiple bending stress waves.

- Force Distribution: The residual stress from the material’s previous forming processes is supported by the support rolls, with multiple support roll groups working together to significantly improve the stress state during the leveling process, which is beneficial for the transmission of leveling pressure.

- Result: This results in a uniform distribution of the plate’s residual stress, making it suitable for various industries such as engineering machinery, clean energy, automotive, metal structures, new materials, pressure vessels, chemical machinery, and more.

6-HIGH LEVELING PRINCIPLE

- Principle: Similar to the four-high principle, but with additional rolls for more complex material deformation and control.

- Advantage: The six-high design allows for more precise control over the leveling process, especially beneficial for materials with more complex stress patterns or those requiring finer finishing.

- Applications: Ideal for industries where extreme precision and surface quality are required, such as in the manufacturing of high-precision components for aerospace, automotive, or high-end equipment.

Roller Box Draw-Out Technology

- Design: The leveling rolls and support rolls are mounted on a removable plate, which can be taken out from the rear bearing of the upper frame.

- Maintenance and Cleaning: This design allows for easy maintenance and cleaning of the leveling rolls and support rolls as they can be removed from outside the machine, reducing the downtime and labor required for maintenance.

- Efficiency: The roller box draw-out technology enhances the accessibility and convenience of the machine, significantly reducing the time needed for roll changes, cleaning, and maintenance, thus improving the overall efficiency of the leveling process.

CNC Series Model Comparison Guide

Uncover a diverse array of products meticulously crafted to fulfill your unique needs. If you’re feeling uncertain about which option is the best fit for you, please feel free to reach out to us anytime. Our dedicated team is eager to guide you through your options and help you find the perfect match.

Model JZ-20 To JZ-50

Model JZ-60 To JZ-120

Model JZ-150 To JZ-260

Model-Z

Model JZ-20 To JZ-50

Model JZ-60 To JZ -120

Model JZ-150 To JZ-260

Max.criteriom width

200-1300mm To 400-2200mm

400-2200mm To 400-3800mm

400-3800mm

Roller diameter

20mm-50mm

60mm-120mm

150mm-260mm

Max.thickness

1.5mm-4mm

6mm-16mm

25mm-60mm

Thickness range

0.2-1.5mm To 0.8-4mm

1-6mm To 4-16mm

6-25mm To 15-60mm

Min.work-piece size

10x40mm-15x100mm

15x120mm-60x200mm

60x280mm-60x520mm

Leveling speed

0-12m/min

0-12m/min

0-12m/min

Leveling roller gap

adjust method

Four points auto. Adjust driven by servo motors

Four points auto. Adjust driven by servo motors

Four points auto. Adjust driven by servo motors

Request Your Quote Today

Looking to enhance your metal processing capabilities? Contact us now to get more information or request a quote for our top-of-the-line leveling machines. Our experts are ready to assist you in finding the perfect solution for your industrial needs.