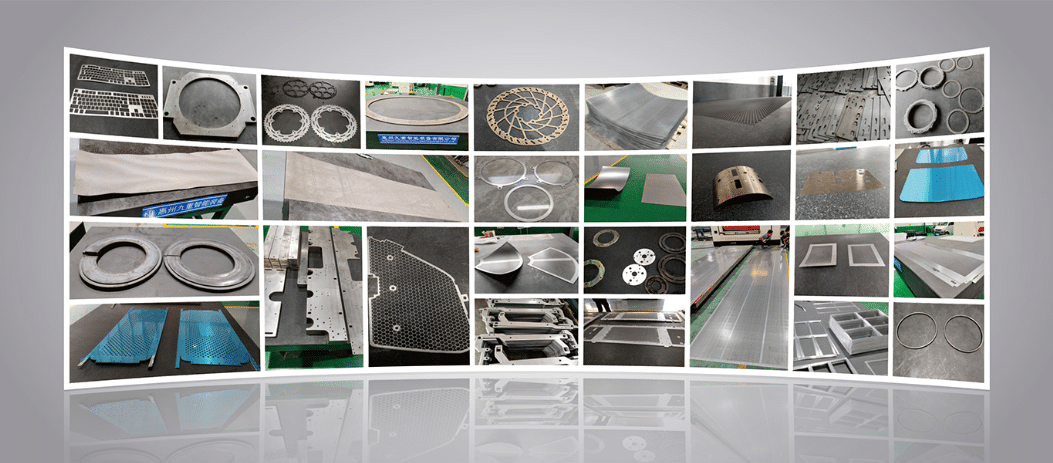

Did you know that the sleek smartphone in your pocket and the massive hull of an ocean-going vessel share a common manufacturing heritage? Both rely on the precision of sheet metal leveling machines, sophisticated equipment that transforms raw metal sheets into perfectly flat, uniform components essential for modern manufacturing.

From the intricate world of medical devices to the towering structures of renewable energy, sheet metal leveling machines serve as the unsung heroes of industrial production. These versatile machines ensure the structural integrity, aesthetic appeal, and functional precision that define today’s manufactured products across a remarkable spectrum of industries.

1. Automotive Industry

Sheet metal leveling machines play a central role in manufacturing car bodies, panels, and structural parts. These machines create precise, flat surfaces that advance aerodynamics and reduce fuel consumption. Modern electric vehicle facilities implement roller levelers to produce battery enclosures and lightweight body components, meeting exact specifications for next-generation automobiles.

2. Aerospace and Aviation

Sheet metal fabrication is essential in producing aircraft fuselages, wings, and other structural elements. The technology maintains uniform thickness across metal sheets, reducing assembly errors and supporting flight safety. Commercial airplane manufacturers use these machines to create lightweight structures, helping to lower fuel usage and operating costs.

3. Construction and Building Materials

Sheet metal fabrication supports the production of construction frameworks, façades, and metal roofing materials. The process strengthens structural components while minimizing material waste in building projects. Modern architecture increasingly incorporates metal elements, with a notable rise in sustainable building designs that require perfectly flat, strong metal sheets for optimal performance.

4. Electronics and Appliance Manufacturing

Sheet metal leveling machines support production of casings and components in electronics manufacturing. The process makes parts that fit together with high accuracy and disperse heat properly. Applications range from small smartphone housings to large appliance frames. The part leveling machines create consistent metal surfaces needed for both consumer electronics and high-efficiency appliances production.

5. Heavy Machinery and Equipment

Sheet metal fabrication supports the manufacturing of tankers, loaders, and industrial equipment components. The process creates strong, flat surfaces that last longer and need less maintenance over time. Manufacturing facilities report better production rates and higher product quality when making heavy equipment parts using metal leveling methods.

6. Shipbuilding and Marine Industry

Sheet metal fabrication shapes hulls and structural parts in modern shipbuilding. The technology creates metal sheets with tight tolerances needed for water-tight seals between hull sections. These machines process large metal sheets to exact specifications, supporting fluid movement through water and reducing drag. Ship manufacturers rely on this process to maintain consistent thickness across extensive metal surfaces used in vessel construction.

7. Renewable Energy Sector

Sheet metal fabrication creates components for solar panel mounting systems and wind turbine parts. The technology produces metal elements that maintain proper positioning and structural stability over long periods. Real-world results show improved output at wind farms that incorporated parts made with advanced leveling methods. The process helps solar and wind energy manufacturers make reliable, long-lasting equipment for sustainable power generation.

8. Home Appliance Manufacturing

Sheet metal leveling machines create strong, attractive stainless-steel appliances. The process makes refrigerators and washing machines with smooth, even surfaces that stand up to daily use. Production lines benefit from this technology, making appliances with better-fitting parts and polished finishes. High efficiency leveling machines result in appliances that look good and work well for longer periods.

9. HVAC Systems Production

Sheet metal fabrication is fundamental in making ducts and external casings for HVAC equipment. The technology creates components that allow smooth airflow and better system operation. Tests show that metal sheets processed through levelers before manufacturing outperform those adjusted after production, leading to more effective heating and cooling systems.

10. Metal Furniture Manufacturing

Sheet metal fabrication forms the foundation of modern metal furniture production, creating precise surfaces for tables, chairs, and storage units. The technology produces flat, strong components that fit together without gaps or instability. Production facilities report higher output rates in modular furniture assembly lines using leveled metal sheets, with fewer defects and material waste in the final products.

11. Steel Service Centers

Metal processing facilities work with leveling machines to supply flat metal sheets across industries. Their operations streamline metal supply chains and maintain high product standards. Steel centers offer multiple processing options including leveling, slitting, and custom metal sheet preparation based on client requirements. Working with these centers reduces production time and material waste for manufacturers.

12. Metal Packaging Industry

Sheet metal fabrication supports can and lid production for food and beverage packaging. The machines create metal sheets with exact thickness measurements, leading to better seals and storage properties. The process makes containers that maintain product freshness and stand up to shipping stresses. Metal packaging manufacturers count on flat, properly shaped materials to make reliable containers that protect contents during storage and transport.

13. Agricultural Equipment Manufacturing

Sheet metal fabrication supports manufacturing of tractor components, plows, and farming machinery parts. The process creates strong metal surfaces that resist wear in harsh field conditions. Modern farming equipment producers integrate these metal components into automated systems and precision agriculture tools, improving durability and function across their product lines.

14. Railway and Transportation Equipment

Sheet metal fabrication forms key components in train manufacturing and rail infrastructure. The process creates metal parts that meet strict safety standards while reducing ongoing repair needs. Modern production facilities use these machines to make uniform, strong parts for trains, tracks, and related transportation systems, supporting reliable operation across rail networks.

15. Medical Device Manufacturing

Sheet metal fabrication is vital in making surgical tables and medical equipment casings. The process creates surfaces with exact measurements needed for sterile medical settings. Manufacturing facilities produce medical devices with tight specifications, resulting in equipment that works consistently and safely in healthcare operations.

Conclusion

The widespread adoption of sheet metal leveling machines across diverse industries underscores their fundamental importance in modern manufacturing. From automotive bodies to solar panel frames, these machines create the precise, uniform metal surfaces that enable technological advancement and industrial efficiency. Their impact extends far beyond simple metal processing, touching virtually every aspect of our manufactured world.

As industries continue to evolve and demand higher precision and quality standards, sheet metal leveling machines remain at the forefront of manufacturing innovation. Their ability to produce consistently flat, stable metal components makes them indispensable tools in the pursuit of manufacturing excellence, supporting everything from sustainable energy solutions to life-saving medical equipment.

0 Comments